Bioprocess Engineering: Design of Biological Manufacturing Systems

Introduction

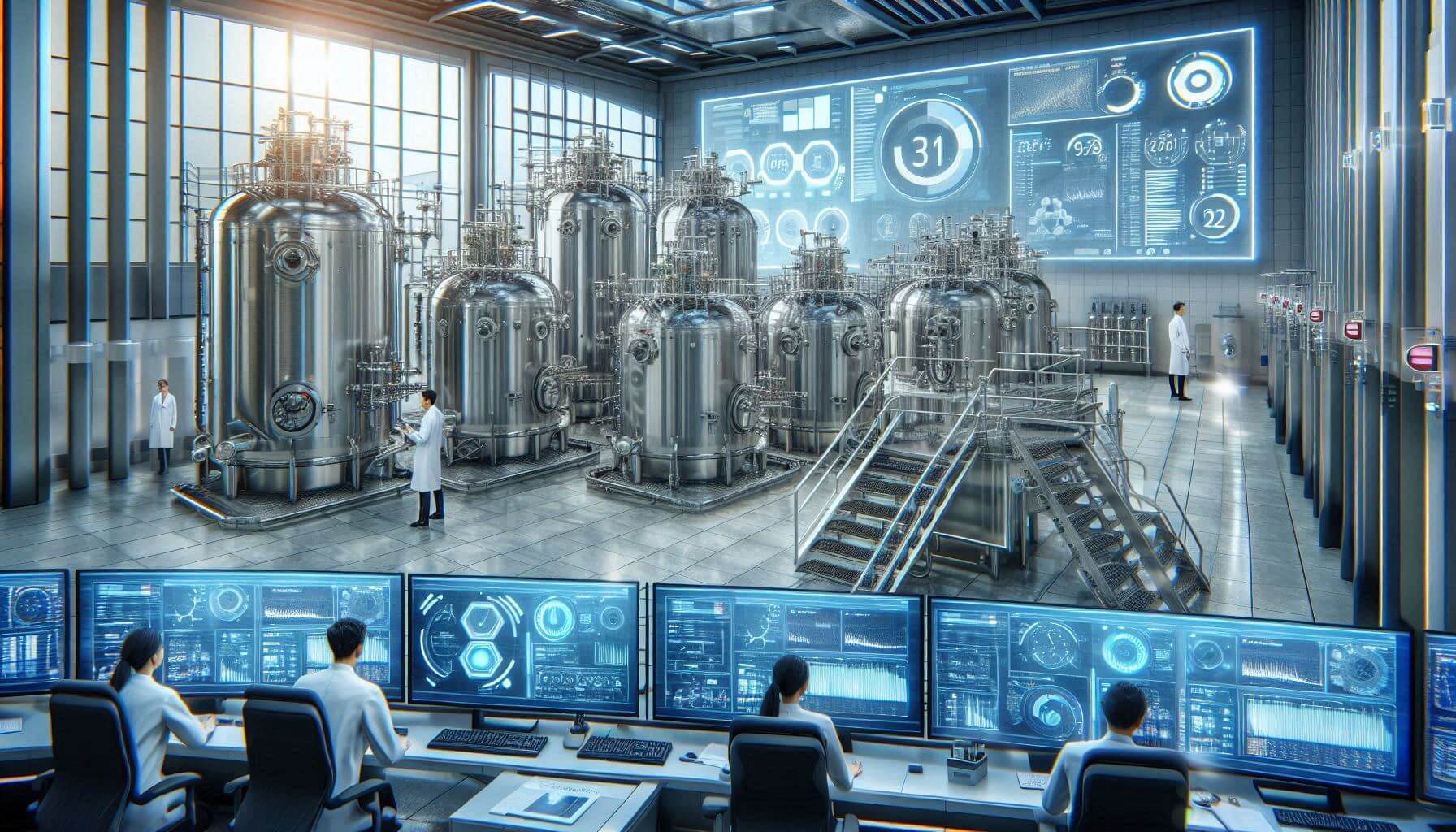

Bioprocess engineering is at the forefront of designing efficient biological manufacturing systems, playing a crucial role in industries ranging from pharmaceuticals to biofuels. It integrates biological organisms or their derivatives to produce valuable products. In this article, we will delve into the principles of bioprocess engineering for manufacturing, focusing on system design, process optimization, and its industrial applications.

The primary focus will be on bioprocess engineering for manufacturing, including biological manufacturing system design and biomanufacturing system optimization. Additionally, the critical factors that contribute to successful biomanufacturing, such as scalability, sustainability, and process control, will be explored.

Defining Bioprocess Engineering

Bioprocess engineering involves the design and development of processes that use biological organisms or molecules to manufacture products such as pharmaceuticals, food, and biofuels. This field merges biological science with engineering principles to optimize the efficiency and sustainability of manufacturing systems.

At its core, bioprocess engineering applies to both upstream processing, which involves the growth of cells or microorganisms (fermentation, cell culture), and downstream processing, which includes product recovery and purification. The process must be meticulously designed to ensure product quality, scalability, and cost-effectiveness.

Components of a Bioprocess System

Upstream Processing

Upstream processing is the first phase of biomanufacturing, where the biological components are grown or synthesized. This often involves fermentation technology, where microorganisms or cells are cultured in bioreactors. The conditions in these bioreactors, including temperature, oxygen levels, and pH, must be tightly controlled to ensure optimal growth and product formation.

The development of cell cultures and enzyme production systems are critical components of upstream processes. These technologies are utilized in fields like pharmaceuticals, where cells produce therapeutic proteins or enzymes that require large-scale production.

Downstream Processing

Downstream processing refers to the extraction, purification, and recovery of the products generated during upstream processing. This stage often involves filtration, centrifugation, and chromatography to isolate the desired product. Ensuring efficient downstream processes is essential for high-quality yields and cost-effective production.

Bioreactor Design

The design of bioreactors, a central aspect of bioprocess engineering for manufacturing, is a key determinant of process success. Bioreactors must be designed to accommodate large-scale production while ensuring uniform conditions across the system to avoid contamination and ensure high product quality. Parameters like mixing efficiency, oxygen transfer rates, and heat dissipation are vital in bioreactor design.

Design Principles of Biological Manufacturing Systems

Effective biological manufacturing systems rely on several design principles. These include scalability, cost-efficiency, sustainability, and the use of advanced technology.

Scalability

One of the most critical aspects of bioprocess engineering is ensuring that the system can be scaled up from laboratory settings to industrial-scale production. Biological systems often behave differently at larger scales, and the challenge lies in maintaining product quality and process efficiency. Scaling up bioprocesses requires modifications to bioreactor design, process control systems, and the overall infrastructure to meet the demands of mass production.

Cost-Efficiency

Cost-efficiency is a major consideration in biomanufacturing. The goal is to optimize production processes to reduce operational costs without compromising quality. Techniques such as continuous bioprocessing and automation help streamline the workflow, reduce human intervention, and increase production speed, contributing to cost savings.

Sustainability

The demand for sustainable manufacturing practices has increased in recent years. Bioprocess engineering addresses this by focusing on sustainable biomanufacturing processes that minimize waste, use renewable resources, and reduce energy consumption. Implementing environmentally friendly technologies and reducing the carbon footprint of biomanufacturing systems is a priority for modern industries.

Process Control

Process control in biomanufacturing ensures that the production process is tightly regulated to meet quality standards. Automation in biomanufacturing has advanced rapidly, allowing real-time monitoring and adjustments of critical parameters such as temperature, pH, and oxygen levels. These systems help maintain optimal production conditions, reduce variability, and ensure product consistency.

Applications of Bioprocess Engineering

Bioprocess engineering is applied across various industries, with key applications in pharmaceuticals, food production, and biofuels.

Pharmaceuticals

In the pharmaceutical industry, bioprocessing in industrial applications plays a significant role in the production of biologics, including vaccines, antibodies, and therapeutic proteins. Advances in cell culture bioprocess development have enabled the large-scale production of these biologics, which are essential for treating a wide range of diseases.

Food Production

Bioprocess engineering also contributes to food production by using microbial fermentation to create products like enzymes, amino acids, and probiotics. The field of industrial biotechnology has seen significant advancements in the production of sustainable and nutritious food alternatives, driven by bioprocess technologies.

Biofuels

In the energy sector, bioprocess engineering is utilized in the production of biofuels through biosynthetic pathways. By converting organic matter into biofuels, such as ethanol or biodiesel, bioprocessing offers a renewable alternative to fossil fuels. These processes are key to reducing greenhouse gas emissions and promoting environmental sustainability.

Challenges in Bioprocess Engineering

Despite its many benefits, bioprocess engineering faces several challenges, including contamination risks, process validation, and maintaining product quality.

Contamination Risks

One of the primary concerns in biomanufacturing is contamination. Biological systems are highly sensitive to their environments, and even minor contaminants can ruin an entire batch. Process control systems must be robust enough to detect and eliminate potential contaminants.

Process Validation

Process validation ensures that biomanufacturing systems consistently produce products that meet predetermined specifications. Validation protocols must account for all variables in the system, including equipment performance, raw material variability, and environmental conditions.

Maintaining Product Quality

Ensuring consistent product quality during the scale-up of bioprocesses is a major challenge. Variability in biological systems, such as differences in growth rates or genetic mutations, can affect product yields and quality. Tight regulation of system parameters and real-time monitoring are essential to maintaining product quality at industrial scales.

Future Trends in Bioprocess Engineering

The future of bioprocess engineering is driven by advancements in automation, artificial intelligence (AI), and continuous bioprocessing. These technologies are poised to revolutionize the field by improving efficiency, reducing costs, and enhancing sustainability.

Automation and AI

Automation technologies are increasingly being integrated into biomanufacturing systems. AI-driven process control systems can monitor and adjust production conditions in real-time, improving accuracy and reducing human error. These technologies are especially valuable in complex bioprocesses where small deviations can have significant effects on product quality.

Continuous Bioprocessing

Continuous bioprocessing is another emerging trend in the field. Unlike traditional batch processes, continuous systems allow for the uninterrupted flow of materials through the production process. This approach reduces downtime, increases efficiency, and improves scalability.

Conclusion

Bioprocess engineering is a dynamic field that plays a pivotal role in designing and optimizing biological manufacturing systems. With applications ranging from pharmaceuticals to biofuels, it is integral to the production of high-quality biological products. The design principles of scalability, cost-efficiency, and sustainability, along with advancements in automation and continuous bioprocessing, will continue to shape the future of biomanufacturing.

As the demand for biologically produced goods increases, bioprocess engineering will remain at the forefront of innovation, driving new methods to meet the challenges of modern industrial biotechnology.

Engineering Topics