The Future of 3D Printing in Mechanical Engineering: Applications, Advancements, and Possibilities

The field of mechanical engineering has seen tremendous growth over the past few decades, thanks to technological advancements that have revolutionized the way we design and manufacture products. One such innovation that has caught the attention of mechanical engineers worldwide is 3D printing, also known as additive manufacturing. This technology has opened up new possibilities for design and production, offering a range of benefits that were previously impossible. In this article, we will explore the latest trends, materials, and benefits of 3D printing technology in mechanical engineering design and production. We will also examine the potential and challenges of this innovative technology, providing insights and case studies that demonstrate its impact on the industry.

Overview of 3D Printing Technology and Its Applications in Mechanical Engineering

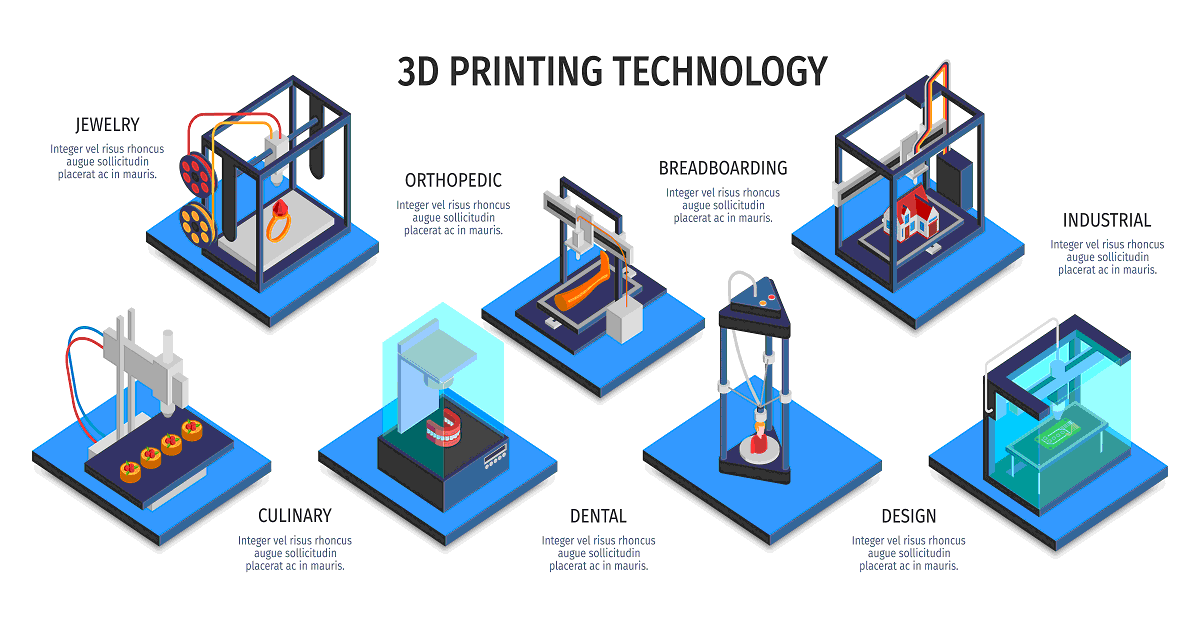

3D printing is a process of creating a physical object from a digital model by adding material layer by layer. It is a form of additive manufacturing that allows engineers and designers to create complex parts and components that would be difficult or impossible to produce using traditional manufacturing methods. 3D printing technology has several applications in mechanical engineering, including:

- Rapid prototyping: 3D printing allows for the quick and cost-effective production of prototypes, enabling engineers to test and refine designs before committing to large-scale production.

- Customization: 3D printing enables the production of custom-made parts and components, allowing for a high degree of personalization and customization.

- Design optimization: 3D printing enables engineers to create complex geometries and internal structures that would be difficult or impossible to produce using traditional manufacturing methods. This allows for the optimization of parts and components, resulting in improved performance and efficiency.

- Production of low-volume and high-complexity parts: 3D printing allows for the cost-effective production of low-volume and high-complexity parts, which would be too expensive or time-consuming to produce using traditional manufacturing methods.

Advancements and Trends in 3D Printing for Mechanical Engineering

The field of 3D printing is constantly evolving, with new materials, technologies, and applications being developed all the time. Some of the recent advancements and trends in 3D printing for mechanical engineering include:

- Improved speed and accuracy: Recent advancements in 3D printing technology have resulted in faster and more accurate printing, enabling the production of high-quality parts and components in less time.

- Multi-material printing: 3D printing technology now allows for the simultaneous printing of multiple materials, enabling the production of parts with different properties and characteristics.

- Metal printing: 3D printing technology can now be used to produce parts and components using metals such as titanium, aluminum, and steel, opening up new possibilities for mechanical engineering.

- Integration with other technologies: 3D printing is increasingly being integrated with other technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM), enabling a more streamlined and efficient production process.

Materials Used in 3D Printing for Mechanical Engineering Applications

The materials used in 3D printing vary depending on the specific application and requirements of the part or component being produced. Some of the most commonly used materials in 3D printing for mechanical engineering applications include:

- Thermoplastics: Thermoplastics such as ABS, PLA, and nylon are widely used in 3D printing for their ease of use and versatility.

- Metals: Metals such as titanium, aluminum, and steel are increasingly being used in 3D printing for mechanical engineering applications, thanks to recent advancements in metal printing technology.

- Composites: Composites such as carbon fiber reinforced polymers (CFRPs) and glass fiber reinforced polymers (GFRPs) are used in 3D printing for their high strength and stiffness.

Benefits of Using 3D Printing Technology in

Mechanical Engineering Design and Production:

3D printing technology has many benefits for mechanical engineering design and production, some of which are outlined below:

1. Cost-effective: 3D printing can be a cost-effective solution for producing low-volume parts or prototypes, as it eliminates the need for expensive tooling and reduces waste material.

2. Design flexibility: With 3D printing, designers have greater flexibility to create complex geometries and shapes that would be difficult or impossible to achieve with traditional manufacturing methods. This can lead to improved product performance and functionality.

3. Customization: 3D printing allows for the production of custom parts and products, which can be tailored to individual customer requirements. This is particularly useful in industries such as aerospace and medical, where customized products are often required.

4. Rapid prototyping: 3D printing enables rapid prototyping, allowing designers and engineers to quickly iterate and refine their designs before final production. This can help to reduce development time and costs.

5. Reduced lead times: 3D printing can significantly reduce lead times for parts and products, as it eliminates the need for tooling and can produce parts on demand.

6. Environmental benefits: 3D printing can be a more sustainable manufacturing solution, as it reduces waste material and energy consumption.

Case Studies and Examples of Successful 3D Printing Applications in Mechanical Engineering:

There are many examples of successful 3D printing applications in mechanical engineering, some of which are outlined below:

1. GE Aviation: GE Aviation has used 3D printing technology to produce fuel nozzles for its LEAP aircraft engines, reducing the number of parts from 18 to 1 and cutting production time by 25%.

2. Volkswagen Autoeuropa: The Volkswagen Autoeuropa factory in Portugal uses 3D printing to produce custom-made tools and fixtures, reducing tooling costs by 90% and production time by 95%.

3. NASA: NASA has used 3D printing to produce rocket engine parts, reducing the number of parts from hundreds to just a few and cutting production time from months to weeks.

4. Renishaw: The UK-based engineering firm Renishaw has developed a 3D printing process called metal powder bed fusion, which allows for the production of complex metal parts with high precision and accuracy.

5. Adidas: Adidas has used 3D printing to produce midsoles for its Futurecraft 4D sneakers, allowing for customization and optimization of cushioning and support.

6. MIT: Researchers at MIT have developed a 3D printing technique that can produce structures up to 10 times faster than conventional 3D printing methods, opening up new possibilities for large-scale production.

Future Possibilities and Potential for 3D Printing in Mechanical Engineering:

The future possibilities and potential for 3D printing in mechanical engineering are vast, and the technology is expected to continue to evolve and improve in the coming years. Some of the potential applications and benefits of 3D printing in mechanical engineering include:

1. Increased automation: 3D printing technology has the potential to significantly increase automation in manufacturing processes, reducing the need for manual labor and improving efficiency.

2. On-demand production: 3D printing enables on-demand production of parts and products, reducing inventory costs and lead times.

3. Customization: 3D printing allows for the production of customized parts and products, which can be tailored to individual customer requirements.

4. Reduced waste: 3D printing can significantly reduce waste material and energy consumption, making it a more sustainable manufacturing solution.

5. Improved product performance: 3D printing enables the production of complex geometries and shapes, which can lead to improved product performance and functionality.

Challenges and Limitations of 3D Printing in Mechanical Engineering:

Despite the many benefits and potential applications of the world to the modern infrastructure that we rely on today. With the advancements in technology, the field of civil engineering has evolved, and new technologies like 3D printing are being adopted to streamline the construction process and enhance the quality of structures.

3D printing technology has several benefits in civil engineering, including reduced costs, improved design flexibility, and faster construction times. This technology has already been used to construct complex structures like bridges, buildings, and even entire homes. As the technology continues to develop, we can expect to see more innovative uses for 3D printing in civil engineering, leading to more efficient and sustainable construction practices.

Conclusion

In conclusion, 3D printing technology is a game-changer for the field of civil engineering, and it has the potential to revolutionize the way we design and construct structures. With its many benefits, it's no surprise that 3D printing is quickly becoming a preferred method for architects and engineers. As the technology continues to advance, we can expect to see even more exciting developments in this field.

Engineering Topics Mechanical Engineering